| H*W (mm) | H*W (mm) | H*W (mm) | H*W (mm) | H*W (mm) | H*W (mm) | H*W (mm) | H*W (mm) | H*W (mm) |

| 0.3*0.8 | 0.4*0.8 | 0.5*1.0 | 0.6*1.0 | 0.7*1.5 | 0.8*1.7 | 1.0*2.3 | 1.2*3.0 | 1.4*4.0 |

| 0.3*1.0 | 0.4*1.0 | 0.5*1.2 | 0.6*1.2 | 0.7*1.7 | 0.8*1.9 | 1.0*2.5 | 1.2*3.2 | 1.4*4.5 |

| 0.3*1.2 | 0.4*1.2 | 0.5*1.3 | 0.6*1.3 | 0.7*1.9 | 0.8*2.1 | 1.0*2.7 | 1.2*3.5 | 1.4*5.0 |

| 0.3*1.4 | 0.4*1.3 | 0.5*1.4 | 0.6*1.4 | 0.7*2.1 | 0.8*2.3 | 1.0*3.0 | 1.2*4.0 | 1.4*6.0 |

| 0.3*1.5 | 0.4*1.4 | 0.5*1.5 | 0.6*1.5 | 0.7*2.3 | 0.8*2.4 | 1.0*3.2 | 1.2*4.5 | 1.4*7.0 |

| / | 0.4*1.5 | 0.5*1.6 | 0.6*1.6 | 0.7*2.5 | 0.8*2.5 | 1.0*3.5 | 1.2*5.0 | / |

| / | 0.4*1.6 | 0.5*1.7 | 0.6*1.7 | 0.7*2.7 | 0.8*2.7 | 1.0*4.0 | 1.2*6.0 | / |

| / | 0.4*1.7 | 0.5*1.9 | 0.6*1.9 | 0.7*2.8 | 0.8*3.0 | 1.0*4.5 | / | / |

| / | 0.4*1.9 | 0.5*2.1 | 0.6*2.1 | 0.7*3.0 | 0.8*3.2 | 1.0*5.0 | / | / |

| / | / | 0.5*2.5 | 0.6*2.3 | 0.7*3.2 | 0.8*3.5 | 1.0*6.0 | / | / |

| / | / | 0.5*2.7 | 0.6*2.5 | 0.7*3.5 | 0.8*4.0 | / | / | / |

| / | / | / | 0.6*2.7 | 0.7*4.0 | 0.8*4.5 | / | / | / |

| / | / | / | 0.6*3.0 | / | 0.8*5.0 | / | / | / |

| / | / | / | 0.6*3.2 | / | 0.8*6.0 | / | / | / |

| / | / | / | 0.6*3.5 | / | / | / | / | / |

| / | / | / | 0.6*4.0 | / | / | / | / | / |

| / | / | / | 0.6*5.0 | / | / | / | / | / |

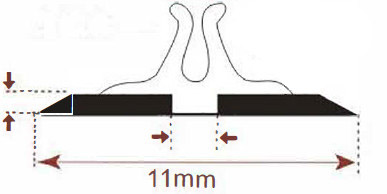

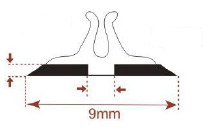

| Model | Paper card thickness | Distance between creasing rule | Bulge height | Creasing matrix thickness | Bulge width | Creasing rule height |

| LQ-B1 | 175-250 | 2.0 | 0.5 | 0.4 | 0.7 | 23.0 |

| LQ-B2 | 250-350 | 2.7 | 0.7 | 0.4 | 1.0 | 22.8 |

| LQ-B3 | 350-450 | 4.0 | 0.9 | 0.4 | 1.5 | 22.6 |

| LQ-B4 | 450-550 | 4.5 | 1.1 | 0.4 | 2.0 | 22.4 |

| LQ-B5 | 550-700 | 5.0 | 1.3 | 0.4 | 2.5 | 22.0 |

| LQ-B6 | 700-1000 | 6.0 | 1.8 | 0.4 | 3.0 | 21.7 |

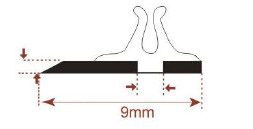

PVC based board Product flexibility, easy to repair Usually used in paper丿am and corrugated die-cutting indentation Die-cutting indentation about 30000-40,000 times The most complete specifications, good stability, cost-effective commonly used creasing matrix . These creasing matrix are suitable for short and medium board products such as paper jam, corrugated packing box and so on.

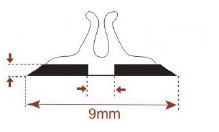

PVC based board Product flexibility, easy to repair Usually used in paper丿am and corrugated die-cutting indentation Die-cutting indentation about 30000-40,000 times The most complete specifications, good stability, cost-effective commonly used creasing matrix . These creasing matrix are suitable for short and medium board products such as paper jam, corrugated packing box and so on. Imported high density fiber pressboard material for base. High hardness, high temperature resistance, wear resistance, easy to repair plate, no delamination. Die-cutting indentation about 50000-80,000 times high die-cutting precision and is suitable for long die plate working. These creasing matrix are suitable for paper jam, corrugated packaging box and other box products. eg: medicines box, wine box, cosmetics box, toothpaste box and other long plate packaging box.

Imported high density fiber pressboard material for base. High hardness, high temperature resistance, wear resistance, easy to repair plate, no delamination. Die-cutting indentation about 50000-80,000 times high die-cutting precision and is suitable for long die plate working. These creasing matrix are suitable for paper jam, corrugated packaging box and other box products. eg: medicines box, wine box, cosmetics box, toothpaste box and other long plate packaging box.

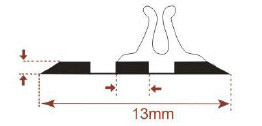

The bottom plate base is PVC material , and the creasing matrix is reversely bent Plastic template, when cut from the reverse direction to produce the indentation of the special process Perfect solve the die cutting of bell mouth problem . Simple operation, and the effect is remarkable.

The bottom plate base is PVC material , and the creasing matrix is reversely bent Plastic template, when cut from the reverse direction to produce the indentation of the special process Perfect solve the die cutting of bell mouth problem . Simple operation, and the effect is remarkable. Use special creasing matrix for U beng-corrugated color box, can die-cut perfect U crease.

Use special creasing matrix for U beng-corrugated color box, can die-cut perfect U crease. | H*W(mm) | H*W(mm) | H*W(mm) | H*W(mm) |

| 0.6*5.0 | 0.7*5.0 | 0.8*5.0 | 1.0*5.0 |

| 0.6*6.0 | 0.7*6.0 | 0.8*6.0 | 1.0*6.0 |

| 0.6*7.0 | 0.7*7.0 | 0.8*7.0 | 1.0*7.0 |

| / | 0.7*8.0 | 0.8*8.0 | 1.0*8.0 |

| / | 0.7*9.0 | 0.8*9.0 | 1.0*9.0 |

Standard corrugated special creasing matrix, ultra wide base design can effectively solve indentation trauma.

Standard corrugated special creasing matrix, ultra wide base design can effectively solve indentation trauma.